How to Select and Identify the Quality Materials of Sex Toys

TPE soft rubber is widely used in the sex toy industry. The hardness and physical properties of TPE materials are different for different functional products.

What are the main materials of sex toys?

From the material requirements, sex toys material should have a good stretch and stretch, soft and comfortable touch, because it is in contact with the human body and skin, must be non-toxic odorless, non-allergic to human skin or side effects.

It is learned that General high-end sex toys are used as basic material SEBS. SEBS is the hydrogenation product of SBS. SBS is made by block copolymerization of styrene and Butadiene. SEBS modified TPE can achieve a variety of required softness, therefore, according to different needs, TPE will be made as a hardness of different materials.

Tpe Sex toys special soft hardness TPE materials, hardness of 0,3,5,8,10,15 degrees material. The hardness of TPE is related to the molecular weight, oil content and PP content of SEBS.

1. TPE10 ~ 15 degree material

Generally used in the production of female false penis, for thick or solid products, hardness is generally 10 ~ 15 degrees of transparent TPE (based SEBS) , or TPR (based SBS) . The TPR cost of SBS base material is lower than that of SEBS base material TPE, but TPR materials are more easy to change color and have poor tactility and tensile property, the processing mode is injection molding.

TPE0 to 10 degrees

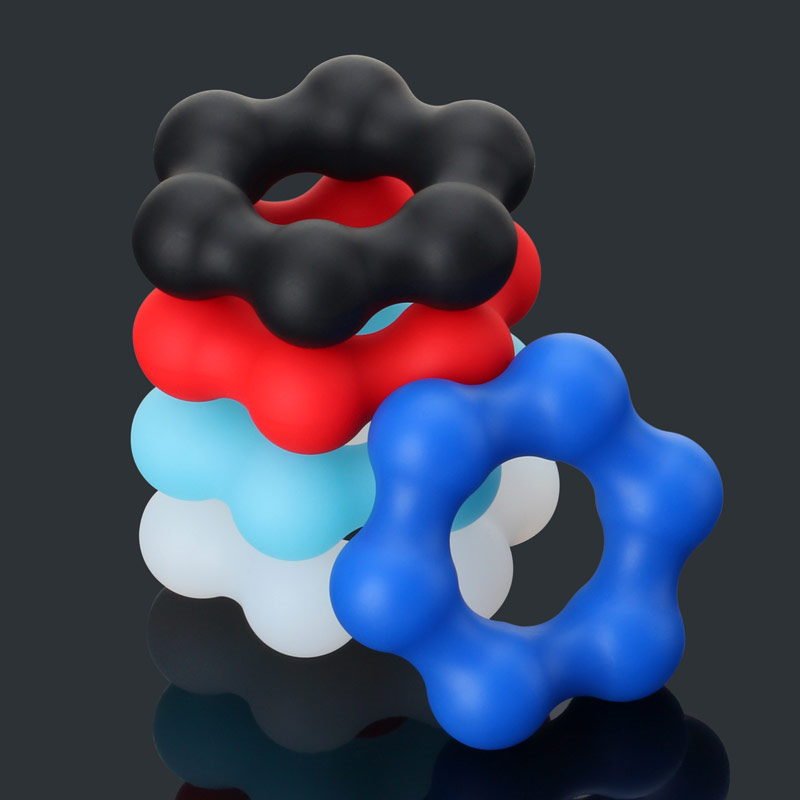

Generally used for the production of women with vibration ring, bow and other accessories, vibration ring needs about 5 degrees of hardness TPE. High Requirements for transparency and tensile strength. Base color, then according to different manufacturers, general base material using SEBS or SEEPS as the basis, processing method for injection molding.

3. TPE0 or below

TPE0 degrees of material (such as 00,000 or with C, C as a measure of shore hardness a 0 degrees below the hardness of ultra-soft materials) , for the production of toys for men, such as aircraft cups, aircraft sets, forming process can choose pouring, injection molding and other ways.

4. TPE super soft

At present, sex toy manufacturers TPE material transparency requirements are relatively high, material background color requirements transparent, not yellowing. The transparency of TPE raw materials is mainly affected by two factors, one is the choice of origin and brand of SEBS substrate, the general import of SEBS substrate TPE, its transparency will be better than domestic. Second, the injection temperature of TPE soft material during processing, sometimes low injection temperature will affect the transparency of products, especially for high molecular weight SEBS modified TPE

How to distinguish the quality of the materials of sex toys?

When buying adult articles, how can the naked eye tell what material it is? How to see the sex toys that buy back is good material? How to tell the good from the bad?

1. Oil Penetration test

Performance status: stored for a period of time after natural oil seepage, decay, issued a strong pungent smell.

Reason: It is normal for TPE to leak oil if the raw materials are not up to standard and the raw materials are not proportioned correctly. For example, oil will leak out after one month, but inferior TPE materials will leak oil within a very short period of time, such as within one hour, and emit a strong pungent smell, then this time we need to pay attention to! For example, after a month of storage, with unqualified TPE material made of toys will appear rot phenomenon.

2. Fire Test

Performance status: A little on fire, emitting black smoke.

Reason: The addition of plasticizers and other toxic high-quality materials are not easy to burn, ignite the surface without any scorch marks. Poor quality TPE materials are prone to ignite and emit acrid black plastic fumes due to the addition of large amounts of plasticizer. When extinguished, the charred area becomes black and gives off a pungent odor due to problems with poor quality TPE materials. Here only for reference, not to say that the charred products will not be qualified, many qualified products will have the same situation.

3. Weak acid test

Status: Ph Strip appears red

Reason: adding toxic plasticizer such as o-phthalic acid or o-phthalic acid, pH value into strong acid, high-quality toys pH value of 4-5 was weak acid. The low-grade material and high-grade material were respectively pounded into containers and soaked in weak acid pure water for three days. The results of Ph test showed that the high-grade material was still weak acid, the Ph test paper was yellow-green and weak acid, which was consistent with the Ph value of human body. After the sample material was immersed in pure water for three days, the acidity and alkalinity of the pure water were tested. The inferior product was red and highly acidic, which caused great harm to human body.